The Invention (History) of Reflective Signs

In the beginning of automobiles on roads and traffic, signs were painted in different contrasting colors, but with no reflective qualities whatsoever. So often they were invisible at night when they needed to be seen the most. The issue was that there was no known way to make the signs more visible without using external lighting and power, which was not practical. Roads needed signs that would light up more and be visible from car lights alone. This need sparked the imagination of inventors, and they set out to find a solution to this problem. One inventor, an American, came up with the initial solution.

Percy Shaw, an inventor, developed the Cataphote, also known as glass cats eye reflectors. These small devices marked the beginning of the history of reflective features on signage. In addition to being used on signs, the tiny glass cataphotes were also placed in the middle of roads to increase centerline visibility. As a result of Percy Shaw’s invention, stop signs could now be seen and read at night for the first time. Percy Shaw submitted a patent application in 1927 and his invention was approved. His “Cataphotes” quickly gained popularity and inspired a competition to develop more effective nighttime road sign illumination. In other words, once people saw how he did it, they knew they could do it better.

Before Percy Shaw created the glass cataphote, another inventor was already developing a product that would completely alter how well we see objects at night. Rudolph Potters started experimenting with ways to mass produce tiny, perfectly round retro reflecting spheres in 1914—predating the invention of the cats eye reflector. These spherical glass spheres would reflect like a cataphote but be considerably smaller—about the size of a pinhead’s ball. Unlike Cataphotes, these beads would not be utilized one at a time. Instead, they would be applied widely to create retro reflective surfaces for large areas. These new micro beads were very popular and were used in various applications. After perfecting the process over many years, Mr. Potter applied for and was granted a patent in 1941 for the method and machinery used to make glass beads. This invention serves as the crucial link between early reflecting signs, which were crude and used cataphotes, and modern signs, which use genuine retro reflectivity along the entire surface of the sign.

Initially, reflecting surfaces were made using Potters retro reflective tiny beads in addition to a binder or paint. A couple such examples include road lining and movie screens. Light enters the glass beads, is bent, bounced, and returned to the source, wherever that may be, just like a Cataphote. This is made possible by the bead’s spherical and parabolic shape. With the beads bound together and the surface covered, large areas could be rendered reflective as opposed to the Cataphote, which maybe covered a square inch each. All that is required for the beads to function is for their tops to be exposed so that light may enter and depart. When beads are on top of a surface, they make it retro reflective (note: a fully encased bead will not reflect since light cannot reach it). A surface such as this is called an Exposed Bead surface. You see this type of surface today with the reflective garments that workers wear. All of these applications are significant because it was these innovative uses of glass beads that sparked the next discoveries.

History of Today’s Reflective Traffic Signs (From Road Striping to Reflective Signage)

Before reflective signage, there were reflective road stripes. Glass beads from Potters Beads were poured onto paint as it was drying to make them retro reflective at night. Before Cataphotes, at night, a stop sign could not be seen. However, the stop bar at the intersection, if it had glass beads on it, could be seen. So this was the first solution to the visibility issue. During this same time, Cataphotes began being used on signs and roadways. So you had a situation from the mid teens into the 30’s when small glass Cataphotes or Cats Eyes, and reflective glass beads, provided nighttime visibility for signs and stripes. This was much better than nothing, however, improvements were needed, and those improvement came about in the mid 30’s.

A 3M engineer named Harry Helzer, was given the responsibility of inventing a new technique for manufacturing reflective center lines on roadways in Minnesota, and this is where the history of reflecting traffic signs as we know them today began. The intention was to create a tape that produced the same result as the popular technique of the period, which involved dropping glass beads into wet paint. Essentially, a roll of road marking tape. Harry Heltzer agreed to take on the task of creating this new product and immediately started working on its design. Keep in mind that he had no intention of creating anything other than reflective road stripes. This was most likely because the issue of seeing signs was solved by Cataphotes. At least somewhat. So since 3m made films, it was reasonable to make a road marking tape.

A highway official gave Mr. Heltzer and his team the idea of a glass bead based reflective tape for pavement by suggesting that they embed glass beads into a stripe that could then be applied to a road. This was simple to imagine because glass beads on paint were already widely used. To create such a product, the team’s initial task was to locate microscopic, retro-reflective glass beads that could be embedded inside a carrier like a tape. Mr. Heltzer and his team embedded the beads on one side of double-sided tape that has adhesive on the top and bottom. The result was a roll of reflective striping tape. The idea was that the stripe would be attached to a road using the other side. Heltzer’s invention did reflect light and leave a reflecting stripe on the pavement. However, maintaining the stripe’s adhesion to a chilly Minnesota road and keeping it reflective for an extended amount of time was a challenge. Basically, the product needed to function just as effectively as reflective paint in order to be commercially feasible. The device therefore functioned, but not well enough to be put to use in a business setting. Even though the initial attempt to produce reflective road striping on a roll failed, it did inspire the development of another incredible technology that forever altered nighttime safety.

(Note – 3m did not give up on reflective road striping and later on in 1974, patented a product that we now know as Stamark. Reflective road stripes on a roll.)

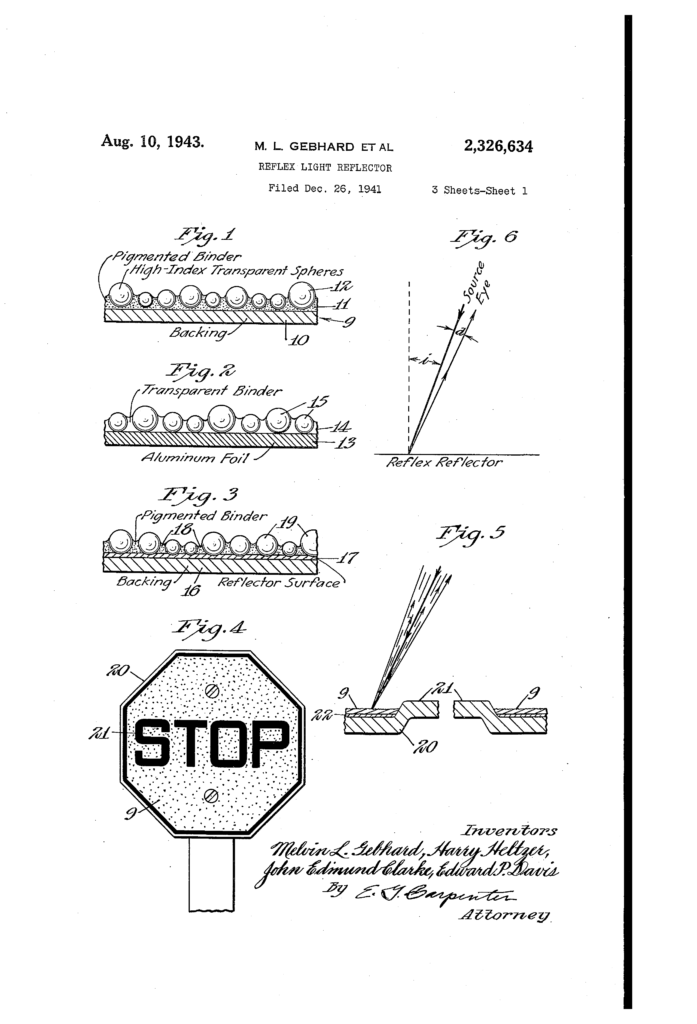

As can be seen by the patent mentioned above, Harry Heltzer and his group started working on a new innovation with the information and expertise they had obtained from reflective road striping. This new invention would eventually grow into a product known as engineer grade reflective sign sheeting. a product that is still very much in use tody. It was intended to adapt the less successful road stripe design to a sign, where road wear was less of a concern. Whatever the case, the invention initially consisted of a workable, if somewhat primitive, design. Issues included a lack of reflectivity overall, bead contamination, and wet reflectivity, to name a few.

The new product’s initial versions merely inserted glass beads into a film’s surface and left them exposed so they might reflect light. Similar to the road striping product, which had exposed beads on top of double-stick tape. The film was afterwards attached to a sign. The reflective sheeting did work to some extent, but when dirt or moisture got in between the beads or when it rained, the beads ceased reflecting enough light to be seen. Overall, the brightness was unsatisfactory even with these problems.

In summation, early prototypes achieved modest reflectivity, which was considerably lower in the rain or when the sheeting accumulated mud and grime. Although this experimentation was a wonderful start, more advancements were undoubtedly required before it could be used commercially. Heltzer and his colleagues then “went back to the design board” and focused on resolving these problems. They required the tape to reflect in all weather conditions, to be brighter, and they also needed a solution to keep the beads clean.

Notation about Glass Bead Reflectivity – A single glass bead will reflect alone on pretty much any surface. When applied in a large area, the apparent reflectivity greatly increases since a multitude of beads are returning light in sync. When on a light colored background they do even better because light is not absorbed by the background. But on a mirrored background, like metallic silver, they reflect incredibly bright. And this is what the team discovered.

A base layer or background on a film that was silver in color, similar to what you would find on the back of a mirror, was developed by 3M to maximize the return of light. This silver surface was covered with perfectly spherical glass beads, half of which were buried in the silver and the other half visible. In essence, the glass bead’s back became a mirror thanks to the silver backing. Not just any mirror either, as the bead’s design allowed for the return of light to its source. In the most basic terms, a retro reflective glass bead with a mirror finish only on the back was developed by 3m. This was an improvement that significantly raised reflectivity. It resolved the brightness problem and partially offset the other problems. But there was still more to be done.

After the film had been made brighter, the problem of it not reflecting when it was dirty or damp had to be solved. It was important to keep the beads protected without impeding their ability to reflect. A very thin, transparent polymer layer was placed on top of the film that encapsulated the beads without affecting reflectivity to shield them. This was tricky, but the engineers solved the problem. The tape was now visible even in rain due to the clear coating, which also prevented the beads from collecting dirt. (Note that different colors can be produced by coloring the top coat.)

3m, in 1939, introduced what is commonly known today as “engineer grade” reflective sheeting. The invention for the film was filed with the patent office in 1941, and officially patented and protected in 1943. The patent was titled, “Reflex Light Reflector“. Trials of the novel product were conducted first in Minneapolis and subsequently in the UK. Reflective signage created with 3M’s new product quickly gained popularity after some time and extensive promotion.

It’s important to note that the film 3m created was CAD or plotter cuttable, making it simple and practical for the industry to create letters. Engineer grade films from 3M could be used as sign backgrounds with non-reflective lettering added on top for contrast. Alternately, letters may be cut out of the material itself so that they would reflect light on a non-reflective surface. Though the former is more common, both options are effective. The engineer grade films and high intensity sheeting from 3M controlled the market for more than 20 years. The inventions underwent further refinements, and other reflective films with a similar design were also made with the same glass bead technology. Whatever the case, as this fresh and inventive picture gained popularity, signs started to illuminate at night all throughout the nation and the world.

The Introduction of Prismatic Retro Reflective Sign Sheeting

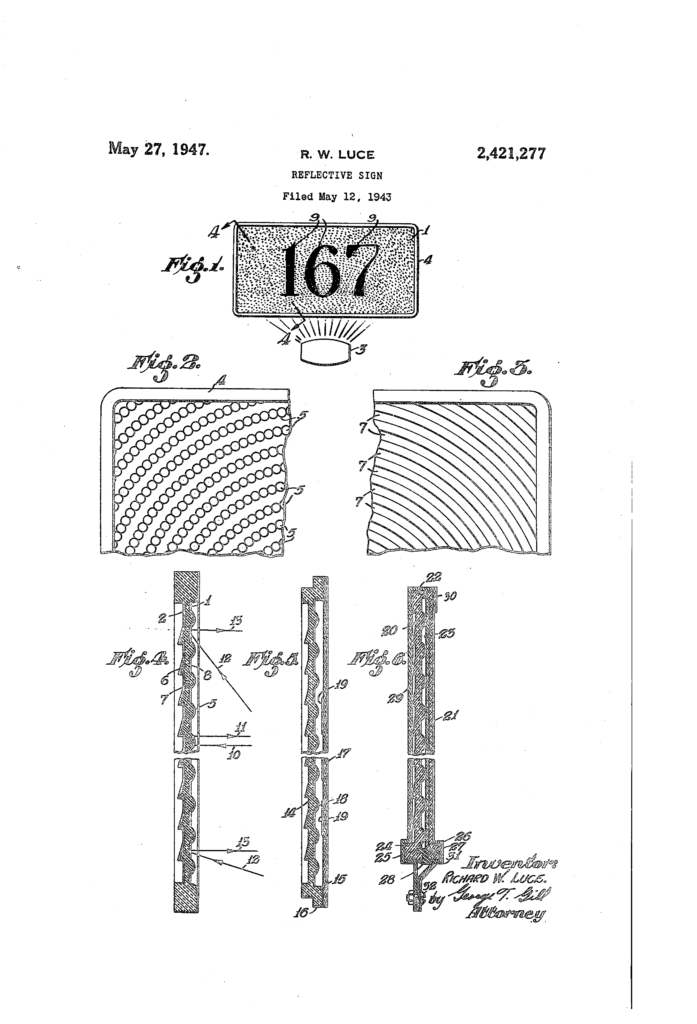

In the realm of retro reflectivity, 3m wasn’t the only corporation or inventor vying for patents. Inventors were experimenting with retro reflective devices employing glass beads and glass or plastic prisms all over the world. In fact, Richard Luce of South Port, Connecticut, applied for a patent for a retro reflective device that didn’t employ glass beads in late 1941, three months before 3m received their patent for engineer grade tape. Instead of glass beads, he employed molded plastic reflectors that, by using angled prisms, duplicated the effects of glass beads. You can get a sense of what Mr. Luce was designing by picturing the reflector on your bike or the back taillight reflector on your car. In any case, this was only the start of his research into artificial prisms and reflectors. After receiving his patent in 1947, Luce carried on innovating and creating new and improved techniques for reflecting light. In the state of Connecticut, he subsequently established a business named Luce Reflexite.

In 1963, two brothers, Hugh and Bill Rowland, who were also working with prisms and retro reflective devices, bought the rights to develop a new retro-reflective technology from Luce Reflexite. And as it would turn out, the Rowland brothers were working on something innovative that would change the world of night time safety, just as much as 3m’s reflective innovations had.

Note – Bill and Hugh Rowland are two Yale Educated engineers and also brothers. Reflexite was the 19th company they had formed. After turning down an offer from 3m to buy the small company, the Rowland brothers decided to sell it over time to the employees using an ESOP. Orafol merged with Reflexite in 2011. A transaction that netted the employee stock holders 40 million dollars. Today, Orafol’s Oralite line of products is the original Reflexite company. Also known as Orafol’s Reflective Solutions division.

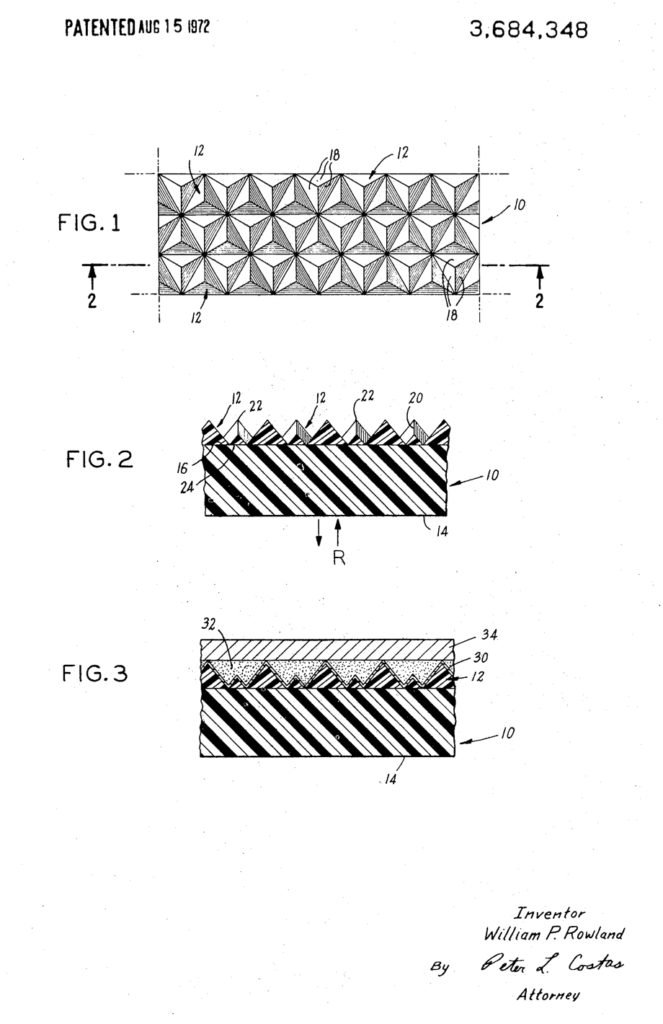

In any event, after securing all the rights , the Reflexite company was formed. They quickly created and patented the worlds first micro-prismatic sheeting or tape, a product that is as much as 20 times brighter than engineer grade films. This meant that signs that before were visible at say 300 feet away, could now be seen from over 3000 feet away. So as traffic moved faster, and roadways became more congested, this was a huge step forward in night time safety on the road. The advantages of such a sheeting are clear, or in the world of retro reflectivity, conspicuous.

Reflexite’s first patent was designated as simply “Retro Reflective Material“, and was filed for in September of 1970. A patent for the novel idea was granted in 1972. This new invention would revolutionize the highway sign industry, vehicle conspicuity, and personal safety. Their new product was not only much brighter, it was also incredibly tough and rugged. This made it perfect for both sign applications which were static, vehicle conspicuity applications which were much more dynamic, and personal safety like garment trims, which are very dynamic. In other words, Reflexite’s new retro reflective film was bright, flexible, versatile, and tough, unlike anything the industry had ever seen.

Numerous further retro reflecting films from Reflexite were patented; and with each iteration, these films improved in reflectivity, vividness, daytime visibility, and adhesion. Reflexite chose to concentrate on vehicle conspicuity since 3m still had a firm grip on the sign sheeting business. As a result, it swiftly overtook 3m as the world’s leading producer of prismatic conspicuity tapes for vehicles. Mainly due to the fact that their product was single-layered, bright, thin, and CAD-cuttable, and it did not delaminate.

Observing what Reflexite had created, 3m patiently awaited the patent to expire before releasing their Diamond Grade reflective sign sheeting. In 1993, they submitted a patent application for their DG sheeting, and they were granted it in 1996. Due to Reflexite’s emphasis on vehicle conspicuity and 3m’s strong marketing capabilities, they were able to convince the sign industry to transition to their new prismatic films very quickly. So although Reflexite sheeting never replaced the sheeting used on signs throughout the world, their invention made it possible.

It’s noteworthy that after working for many years in the retro reflective sheeting sector, Reflexite developed a line of retro reflective films specifically for signage in 2010. This was just before their merger with Orafol. The product was called High Intensity Prismatic or Oralite 5900. It is a vivid air back prismatic that exceeds all ASTM D4956 Specifications for Type 4 sign sheeting. They followed this product up with their 5930 and 5935 High Intensity Prismatic work zone reflective films, also Type 4 rated tapes. A year later, Type 9 Wide Observation Sheeting and Type 11 Brilliant Grade Sheeting were made available by Orafol in Europe. These two items are now marketed in the US as sheeting for traffic signs, together with the 5900 series.

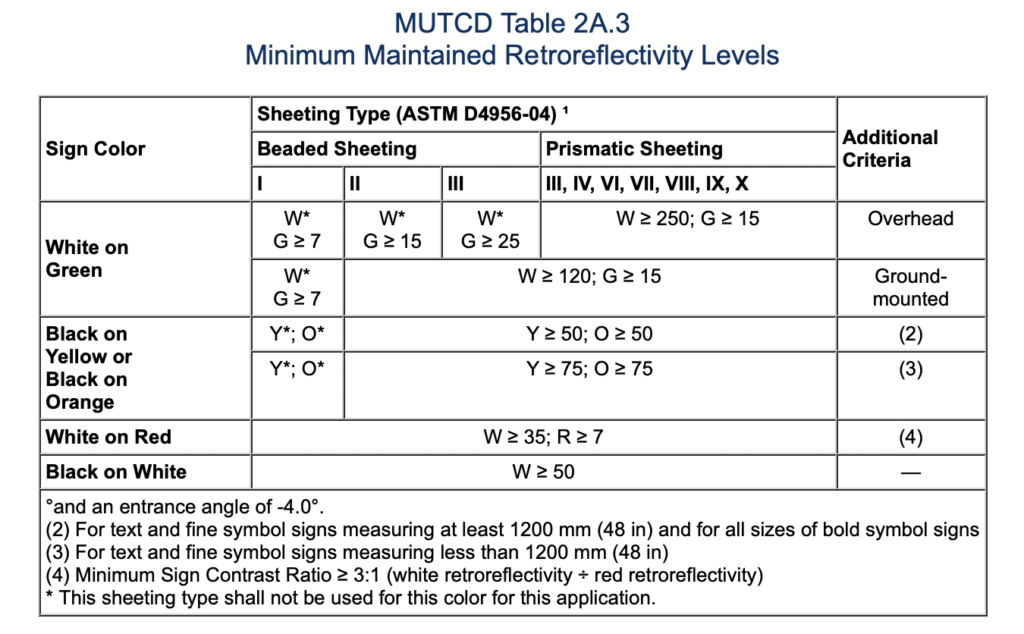

As far as the future goes, given that sign laws have been changing and brighter films are now required across the nation, it is expected that more advanced films will continue to be pushed for traffic signage. As an example, the MUTCD has already eliminated ASTM D4956 Type 1 (engineer grade) as an option for street signs and for all practical purposes, has increased reflectivity requirements to a Type 4 Prismatic sheeting or better. Technically a Type 2 or Type 3 film can be used for certain applications, however, it is not likely that very many municipalities or road agencies will use older technology glass bead sheeting such as type 2 or 3 for new signs. So he timing for the addition of sign sheeting to Orafol’s broad portfolio of reflective films is ideal.

As it stands right now, 3m is the leader in sign sheeting with their Diamond Grade films. However, they are not without competition. Avery, Nikkalite, and of course Oralite are also in the race and are actively competing for their part of a nearly 3.5 billion dollar market for sign sheeting alone. The key will be in the development and marketing of new Type 9 and Type 11 retro reflective films.

Steven Cole (Economics, MBA – University of West Florida , Business & Innovation – Stanford University) 25 years of experience in the reflective safety business. Specializing in vehicle accident and rear end collision reduction through increased visibility.